Most Popular Products

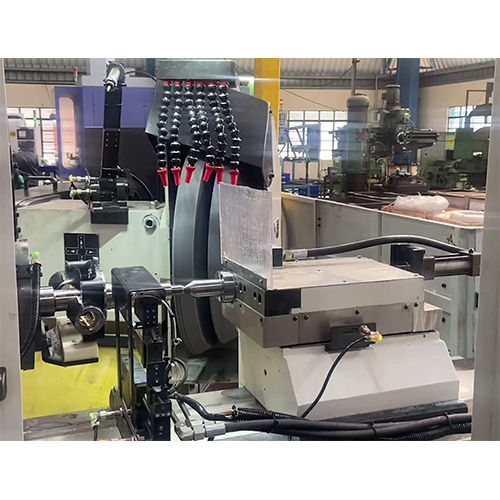

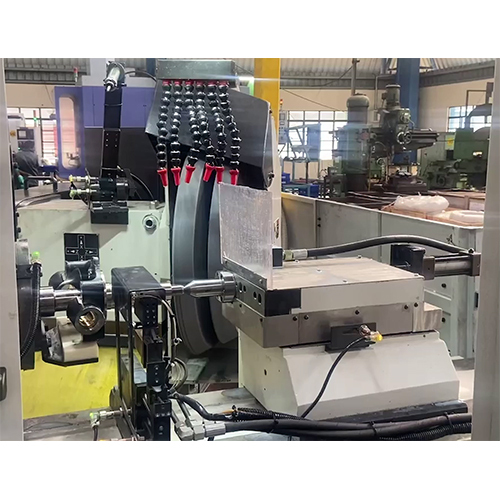

Angular Plunge Grinders

3500000 INR/Number

Product Details:

- Model APG-series

- Rotation Counter-clockwise (viewed from operator)

- Product Type Angular Plunge Grinder

- General Use Precision grinding and angular plunge grinding applications

- Material Cast Iron, Alloy Steel

- Type Surface Grinder

- Capacity High precision batch production

- Click to View more

X

Angular Plunge Grinders Price And Quantity

- 1 Number

- 3500000 INR/Number

- Integrated for table feed

- Automatic centralized lubrication

- Within 0.003 mm

- Built-in with filtration

- ±0.0015 mm

- < 72 dB

- 150 mm

- Electromagnetic

- Up to 0.2 micron Ra

- Emergency stop, overload protection, safety guards

Angular Plunge Grinders Product Specifications

- 2000 x 1400 mm

- Box type Turcite lined ways

- 380 V / 415 V, 3 Phase

- CNC

- Yes

- Angular Plunge Grinder

- 3.5 kW

- Cast Iron, Alloy Steel

- 200 x 400 mm

- Yes

- Industrial grey

- Surface Grinder

- 200 x 13 x 31.75 mm

- High rigidity, low vibration, angular head adjustment

- 200 x 400 mm

- 1450 RPM

- 2100 x 1500 x 1800 mm

- Precision grinding and angular plunge grinding applications

- 1750 kg

- Touch screen/PLC based

- Counter-clockwise (viewed from operator)

- APG-series

- 200 mm

- 1500 RPM

- Not applicable (electric powered)

- High precision batch production

- Integrated for table feed

- Automatic centralized lubrication

- Within 0.003 mm

- Built-in with filtration

- ±0.0015 mm

- < 72 dB

- 150 mm

- Electromagnetic

- Up to 0.2 micron Ra

- Emergency stop, overload protection, safety guards

Product Description

Experience the rare precision of APG-series Angular Plunge Grinders-designed for ineffable accuracy where perfection is paramount. Reduced noise levels (<72dB), a robust 3.5kW motor, and a remarkable surface finish of up to 0.2 micron Ra ensure your shop outperforms the ordinary. With polished performance, advanced CNC controls, and rigorous safety features, these grinders guarantee positioning accuracy within 0.003mm and repeatability of 0.0015mm. The built-in coolant and automatic lubrication systems further extend machine life, while high rigidity and low vibration deliver exceptional results-even as limited models are ending soon.

Salient Features, Commercial Applications & Industry Usages

Angular Plunge Grinders from the APG-series shine with features like integrated hydraulic feeds, touch-screen/PLC controls, electromagnetic chucks, and high-precision grinding. These machines excel in commercial batch production of parts requiring extraordinary surface finishes and tight tolerances. Widely used across automotive, aerospace, and tool manufacturing sectors, they are ideal for both angular plunge and surface grinding at advanced workshops and industrial facilities seeking reliable, high-output machinery.

Packaging, Domestic Market & Certification Details

Each Angular Plunge Grinder is professionally packed using robust export-grade materials, ensuring impeccable condition when handed over after a confirmed purchase order. Delivery estimates vary by location within India, the main domestic market. Every unit adheres to stringent certification requirements, underlining the manufacturer's commitment to excellence and safety. Comprehensive documentation, manuals, and compliance certificates accompany the machine, offering confidence to buyers and seamless integration into production lines.

Salient Features, Commercial Applications & Industry Usages

Angular Plunge Grinders from the APG-series shine with features like integrated hydraulic feeds, touch-screen/PLC controls, electromagnetic chucks, and high-precision grinding. These machines excel in commercial batch production of parts requiring extraordinary surface finishes and tight tolerances. Widely used across automotive, aerospace, and tool manufacturing sectors, they are ideal for both angular plunge and surface grinding at advanced workshops and industrial facilities seeking reliable, high-output machinery.

Packaging, Domestic Market & Certification Details

Each Angular Plunge Grinder is professionally packed using robust export-grade materials, ensuring impeccable condition when handed over after a confirmed purchase order. Delivery estimates vary by location within India, the main domestic market. Every unit adheres to stringent certification requirements, underlining the manufacturer's commitment to excellence and safety. Comprehensive documentation, manuals, and compliance certificates accompany the machine, offering confidence to buyers and seamless integration into production lines.

FAQ's of Angular Plunge Grinders:

Q: How does the automatic lubrication system benefit long-term maintenance?

A: The automatic centralized lubrication system ensures consistent delivery of lubricants to critical components, greatly reducing wear and minimizing manual maintenance, thereby extending the grinder's operational life.Q: What is the process for purchasing and installing this Angular Plunge Grinder?

A: After confirming your purchase order, the grinder is securely packed and handed over for delivery. Once received, installation support and comprehensive documentation help facilitate quick setup and smooth integration into your facility.Q: Where are these Angular Plunge Grinders mainly used?

A: These grinders are typically found in industries such as automotive, aerospace, precision tool manufacturing, and specialized engineering workshops that demand high surface finish accuracy and repeatability.Q: What kind of certifications do these machines come with?

A: All APG-series grinders are supplied with relevant industrial certifications, quality assurance documentation, and operational manuals confirming compliance with industry safety and performance standards.Q: How does the built-in coolant system enhance performance?

A: The built-in coolant system, complete with filtration, keeps the grinding process stable by maintaining optimal temperatures and reducing thermal deformation, ultimately helping achieve fine surface finishes and consistent accuracy.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'CNC GRINDING MACHINE' category

|

PRECITECH MACHINES AND AUTOMATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese